Blow Molding vs Injection Molding - Which is Best?

Among numerous existing plastic molding techniques, injection molding and blow molding are the two most common ones for producing high-quality, low-cost plastic parts. Each technique involves a distinct procedure, and as a result, they differ in a number of ways. Knowing which one to employ is crucial for optimizing the product design and production time, thus saving money and speeding up the delivery of your parts. This article goes through the differences between these two highly utilized plastic molding techniques so you can make a decision on which one better fits your application. Moreover, it gives an overview of each technique separately, but in case you’re still curious about the plastic injection molding method, this Xometry’s guide to injection molding will give you all the information you need.

At a glance:

- What is Injection Molding

- What is Blow Molding

- Injection Molding vs. Blow Molding

- Which Method is Best?

What is Injection Molding

Injection molding is a technique for producing plastic components that involves injecting molten plastic materials into a mold, cooling, and solidifying them. This method plays an important role in the plastic processing industry and is well suited for mass manufacturing of items with complex shapes. The entire plastic injection molding process usually lasts somewhere between 2 seconds to 2 minutes and is made up of several distinct stages.

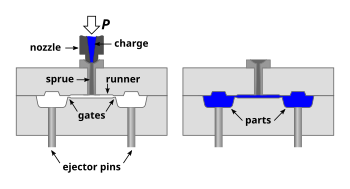

The creation of the mold is the initial step in the injection molding process. Most molds are made from metal, generally aluminum or steel. The mold is made up of two halves, one fixed and the other movable. This is a very important step since the quality of the completed product is largely determined by the design of the mold. The type of mold used determines the strength, durability, form, and size of the product.

After the mold is created, it is attached to the injection molding machine. The mold’s two halves are then squeezed hard against each other with the help of a clamping unit, with one half being able to slide. The material, most frequently in the form of plastic pellets, is fed into the hopper of the machine, which is then poured into a heated plasticizing screw. The pellets are softened and transformed into molten plastic material by the high temperature and the spinning of the screw. Then, this material is injected into the mold at high pressure under the influence of heat. Before the material solidifies, it must be guaranteed that the mold is entirely filled.

After filling the mold, the next step is to cool down the plastic. This is done through cooling channels that follow the shape or profile of the mold cavity. When the plastic solidifies and cools, it adopts the appropriate shape, but it might shrink a little during this process. The cooling time may be calculated using the part’s wall thickness and the thermodynamic parameters of the plastic. Ejection from the machine is the final step of the process. Namely, the mold opens and the component is forcefully pushed out, after which the mold closes again and is ready for a new injection shot.

What is Blow Molding

Blow molding is another method for manufacturing plastic products. Plastic blow molding, just as other molding techniques, uses heated, liquid material that is pressed into a mold cavity under pressure, but it also takes advantage of the features of conventional glassblowing. There are three main thermoplastic blow molding processes: extrusion, stretch, and injection blow molding. Out of these, extrusion blow molding is the most frequently utilized one, so every time we compare the different processes, what we talk about is actually injection blow molding vs extrusion blow molding.

First, plastic pellets are fed into the machine via either a hopper or a screw, depending on the machine that’s being used. The plastic beads or pellets then move through the feed throat as they leave the hopper and are dispensed into a barrel with a big heated revolving screw. In the barrel, the material starts to melt as it is moved forward due to both the frictional shearing forces generated by the rotation of the screw and the heat from external heating bands attached to the feed barrel itself. The molten resin that’s being produced has a gooey consistency similar to bubble gum.

When the melted plastic reaches the screw’s end, it flows over a screen and a breaker plate. This step in the extrusion blow molding process achieves two objectives. Primarily, the screen component of the process is used for eliminating any irregularities or pollutants in the plastic. The breaker plate, on the other hand, alters the plastic’s motion from rotating to longitudinal.

This melted plastic is then extruded in a form of a viscous plastic tube, sometimes known as a “parison”, into a product mold. As the mold closes around the parison, the air is pumped into it and it is inflated against the mold walls. This parison then takes the mold’s shape, cools, and solidifies, after which the mold is opened and the finished plastic part is ejected. Finally, the extra material is removed by a process known as deflashing, and the component is ready to undergo any secondary operations that might be needed.

Injection Molding vs. Blow Molding

While both of the aforementioned plastic molding methods use similar principles—heating the plastic and applying pressure, for example—they ultimately have a large variety of differences which will be covered in the scope of this section.

Molds

To ensure that material flow is completely regulated, injection molds must have a high accuracy match between mold halves. The mold is 90% of the battle when it comes to plastic injection molding. The rest of the procedure should be rather routine after the mold is correctly designed and created. This high precision of the injection mold makes it generally more costly than a blow mold.

Because each mold half generates its unique wall shape, blow molds allow for more design flexibility between mold halves. The mold is only half of the struggle when it comes to blow molding. Variables including wall thinning, air leaks, flash, and streaks are the other half and must be kept an eye on. For example, wall thickness variation is a common consideration for product designers.

Usage of Air

Injection molding’s worst enemy is air since air pockets and bubbles can form if there is air present during the manufacturing process. These anomalies cause the product to have weak spots, resulting in it being deemed faulty and discarded.

Contrastingly, air plays an extremely important role in the plastic blow molding process. Namely, this technique relies on forcing air into the mold in order to expand the product, and thus, without air, blow molding is impossible

Advantages

Some of the injection molding’s advantages include:

- Ability to produce large quantities of tiny pieces that require precise, efficient processing

- Flexibility in sense of the type of material and color that is being used

- Low scrap rates and effective material usage

- Recyclability

The blow molding process offers several different advantages of its own, like:

- Lower costs in comparison to injection molding

- Lower costs of the machinery as well

- Higher level of mold design flexibility

Disadvantages

Now, let’s take a look at some of the main injection molding’s disadvantages:

- High initial costs

- Need of huge machines and tooling

- Restrictions on product design

On the other hand, the disadvantages of blow molding are:

- Applications limited to hollow parts

- Limitations in material since only thermoplastics can be used

- Difficulty to control wall thickness

Which Method is Best?

The most obvious difference between injection molding and blow molding techniques is the type of product that they produce. Generally speaking, injection molding produces solid parts, whereas blow molding produces hollow parts. Plastic injection molding is ideal for mass production in projects requiring hundreds or even millions of identical parts. This method can support more complicated designs than the blow molding procedure and may also be utilized to make parts and products for high-demand applications (e.g., high temperatures or stresses). Engineering-grade polymers, such as ABS, glass-filled nylon, and HTPE, are commonly used for these applications. Furthermore, injection molding may be the best option for anything that requires a single rigid wall. Bottle caps, hair combs, and computer and television housings are just a few examples of items made via injection molding.

On the other hand, blow molding is most likely what you need if you require an item that can be flexible, structural, or retain a fluid. The resultant components’ one-piece structure removes the need for further assembly procedures, resulting in simple and quick production processes. Low total manufacturing costs are a result of these traits, plus the relatively inexpensive machinery that’s used for this type of molding. Water bottles, shampoo and other tiny bottles, automobile components, stadium seats and chairs, watering cans, coolers, and any other hollow parts are examples of parts and products made by blow molding. Plastic Blow molding is used to produce billions of bottles at very low costs. But, in addition to coolers, fuel tanks, and stadium seats, this method may be utilized to create a range of more industrial item designs.

With all of this being said, it’s more than clear that the choice of the molding technique should mainly depend on the type of application, as well as the type of product you wish to produce. Hence, understanding your product’s requirements is the first step in selecting the right molding technique for your product development stage. In addition, here are some questions you should ask yourself before making the decision:

- What are the dimensions of your product in terms of length, breadth, and depth?

- Is your product solid or flexible?

- Should it be food-safe?

- Should it be able to hold liquid?

- Is there a requirement for it to adapt to PSI or certain pressure levels?

- Is the component required to tolerate extremes of heat or cold?

- Is the weight of the object critical to its function?

Conclusion

The main objective of this article was to give you a clearer understanding of the differences between the two main plastic molding methods – injection molding and blow molding. Namely, they utilize different processes, employ different molds, and have distinct advantages and disadvantages. However, the most obvious difference between them, and the number one factor in deciding which method to be used is related to the kind of product that is to be manufactured. Generally, blow molding is commonly used to create single-use, hollow products such as bottles and beakers, while injection molding is used to produce solid products such as plates and discs, as well as solid parts and pieces for plastic items. If you have now decided which method fits your needs and want to take the next step, make sure to ask for your quote and instantly get information about the pricing, lead time, and DFM feedback.

References

- https://prototechasia.com/en/injection-molding/stages-injection-molding

- https://www.creativemechanisms.com/blog/everything-you-need-to-know-about-injection-molding

- https://maycointernational.com/blog/here-is-everything-you-need-to-know-about-blow-molding/

- https://www.sciencedirect.com/topics/engineering/blow-molding

- https://www.petallmfg.com/blog/5-steps-involved-in-producing-an-extrusion-blow-moulded-part/

- https://www.kaysun.com/blog/blow-molding-vs.-injection-molding

- https://www.plasticdesign.com/blow-molding-vs-injection-molding/

- https://www.rodongroup.com/blog/blow-molding-vs.-injection-molding-whats-the-difference

- https://kbdelta.com/blog/plastic-blow-molding-vs-injection-molding.html

Copyright © 2025. All Rights Reserved.